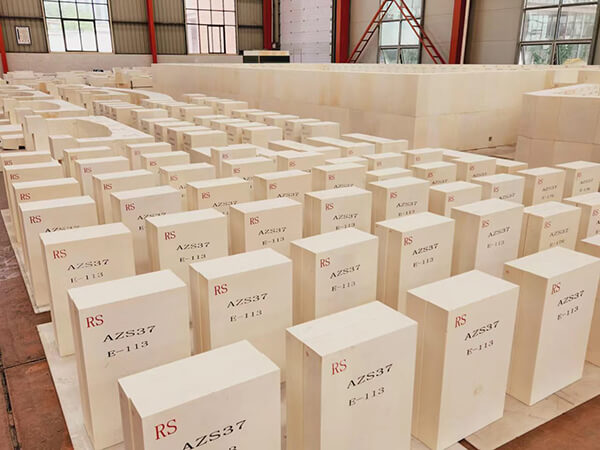

Fused mullite bricks

Al₂O₃ 70-75%, exhibiting high-temperature resistance and thermal shock stability

Application

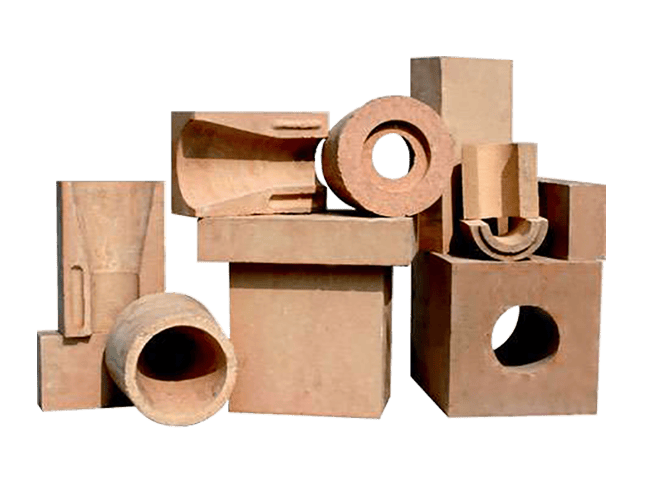

Used in high-temperature zones of: Glass furnaces, Blast furnaces (shaft and hearth), Waste incineration plants, Pyrolysis furnaces, Other metallurgical heating furnaces

Specifications

| Item | Mullite | Zirconium Mullite |

|---|---|---|

| FM-70 | ZM-75 | |

| SiO2% | 16 | 17 |

| Al2O3 % | 75 | 77.5 |

| ZrO2 % | 5 | 2.5 |

| TiO2+CaO+MgO+Na2O+K2O % | 2 | 3.0 (+Fe2O3) |

| Bulk Density g/cm3 | 3.2 | 3.2 |

| Flexural strength MPa | 140 | 140 |

| Cold Crushing Strength MPa | 300 | 300 |

| Thermal conductivity 1300°C W/(m·K) | 5.4 | 4.6 |

| Thermal expansion % 1300°C | 0.9 | 0.8 |

Features

High Thermal Stability

The mullite crystalline structure undergoes no phase transformations at temperatures up to 1600°C, demonstrating superior volumetric stability compared to sintered alternatives.

Corrosion Resistance

This material exhibits exceptional resistance to: Alkaline media (Na₂O, K₂O), Volatile components of glass melts

Energy saving design

Thermal conductivity 15-20% lower than traditional materials, which reduces heat loss of the cooker

Applications

- Heating furnaces for rolling mills – Lining of under-furnace areas

- Furnaces for float glass production – Lining of breast walls and forehearths

- Ceramic roller kilns – Load-bearing bricks for ceramic products

- Pyrolysis furnaces in petrochemistry – Heat-resistant lining of reaction zones

- Waste incineration plants – Lining of the secondary combustion chamber walls

- Rotary cement kilns – Lining of the transition zone

Glass Furnaces

Used for manufacturing molten glass pools, observation windows, etc.

Ceramic Roller Kilns

Low thermal conductivity reduces energy consumption and increases the service life of load-bearing bricks by 300%.

Hazardous Waste Incineration Furnaces

Resistance to slag corrosion from heavy metals and adaptation to abrupt temperature fluctuations.

Dome Furnaces

Used for lining shafts and hearths, exhibiting better thermal shock resistance than fired products.

Related Products