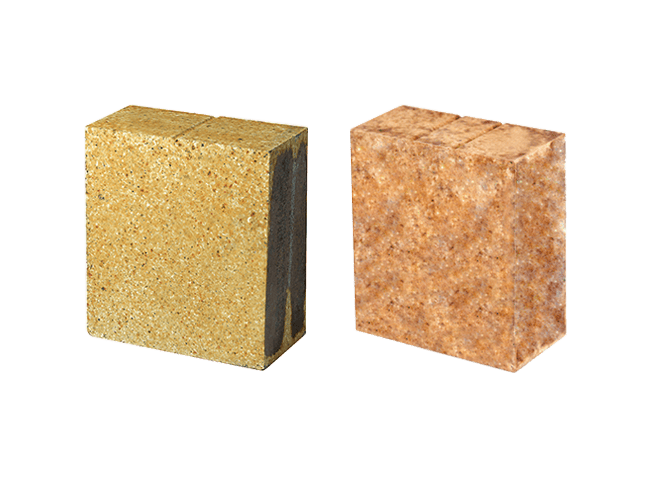

Mullite-SiC brick

Excellent abrasion resistance

Application

Designed for rotary kilns, blast furnaces, and other thermal equipment

Description

Mullite-SiC brick exhibits high compressive strength at room temperature, excellent structural strength at elevated temperatures, good thermal shock resistance, high wear resistance, and exceptional spalling resistance. During operation, it continuously forms a protective layer that resists the penetration of harmful substances such as alkalis and sulfur, demonstrating superior corrosion resistance. The enhanced version utilizes andalusite, which further improves wear resistance.Specifications

| Item | RSAZM-1680 | RSAZM-1650 | RSAZM-1600 | RSAZM-1550 |

|---|---|---|---|---|

| Al2O3 % ≥ | 65 | 65 | 63 | 60 |

| Bulk Density g/cm3 ≥ | 2,65 | 2,65 | 2,60 | 2,55 |

| Apparent porosity % ≤ | 21 | 20 | 20 | 20 |

| Cold Crushing Strength MPa ≥ | 95 | 90 | 90 | 85 |

| Refractoriness Under Load 0.2 MPa °С ≥ | 1680 | 1650 | 1600 | 1550 |

| Refractoriness °С ≥ | 1790 | 1790 | 1790 | 1790 |

| Thermal Shock Resistance (1100 °С-water) ≥ | 15 | 12 | 10 | 10 |

| Wear Resistance ≤ | 8,5 | 8,2 | – | – |

Mullite-Silica Bricks with Andalusite Additives

Purpose of Andalusite Addition:

The incorporation of andalusite in mullite-silica bricks significantly enhances wear resistance.

| Item | GMH1 | GMH2 | GMH3 | |

|---|---|---|---|---|

| Al2O3 % ≥ | 69 | 67 | 65 | |

| Bulk Density g/cm3 ≥ | 25 | 30 | 30 | |

| Apparent porosity % ≤ | 2,7 | 2,65 | 2,65 | |

| Cold Crushing Strength MPa ≥ | 100 | 100 | 100 | |

| Refractoriness Under Load 0.2 MPa °С ≥ | 1660 | 1660 | 1650 | |

| Thermal Shock Resistance (1100 °С-water) ≥ | 25 | 18 | 15 | |

| Wear Resistance ≤ | 7 | 7 | 7 | |

Features

High deformation temperature

Above 1450°CExceptional wear resistance

Mohs hardness: 9.0-9.5High Thermal Stability

Superior Structural StrengthApplications

- Cement Rotary Kilns: transition zone, cooling zone, kiln hood, tertiary air dust

- Magnesite Calcination Kilns: preheating zone, calcination zone

- Mullite Synthesis Rotary Kilns: transition zone, feed pipe, support beam

- Roller Hearth Kilns: combustion chamber

- Lime Calcining Kilns: Lime discharge chute

- Glass Melting Furnaces: regenerator

Repair of Tertiary Air Duct in Cement Kiln

Installation of Mullite-SiC bricks and Magnesium-Alumina Spinel Bricks

Mullite-Silica Bricks with Andalusite Additives