Refractory materials for Aluminum Industry

The aluminum industry imposes extremely high demands on refractory materials, which must not only withstand high-temperature environments but also resist erosion from molten aluminum and slag. High-quality refractory materials are a critical factor in ensuring production efficiency and product quality in aluminum smelting.

Thermal Resistance

Erosion Resistance

Performance Balance

PRODUCT TYPES

We provide a full range of refractory materials for aluminum smelting, professionally designed for different equipment and process stages to meet diverse customer needs.

Refractories for Aluminum Melting Furnaces

Aluminum melting furnaces are critical equipment in aluminum smelting, requiring refractories with exceptional high-temperature resistance, molten aluminum erosion resistance, and thermal shock stability. Our refractory series for aluminum melting furnaces includes:

High-Alumina Refractory Bricks – for furnace walls and roofs

Phosphate-Bonded High-Alumina Bricks – for molten bath areas

Silicon Nitride-Bonded Silicon Carbide Bricks – tap holes, riser tubes, thermocouple

Unshaped Refractories

Refractories for Holding Furnaces

Holding furnaces are used for maintaining temperature and settling of molten aluminum, requiring strict temperature uniformity and insulation performance. Our refractory series for holding furnaces includes:

High-Alumina Refractory Bricks – for furnace walls and roofs

Silicon Nitride-Bonded Silicon Carbide Bricks – tap holes, riser tubes, thermocouple

Lightweight Castables – for insulation layers

Ceramic Fiber Products

Refractories for Aluminum Electrolysis Cells

Aluminum reduction cells are the core equipment in electrolytic aluminum production, operating in extreme environments that require resistance to high temperatures, strong electric fields, and electrolyte corrosion. Our refractory series for reduction cells includes:

Cathode Carbon Blocks

Silicon Carbide Bricks – for cell sidewalls

Insulating Dry Barrier

Carbon Ramming Pastes – Cold and hot ramming pastes

APPLICATION EXAMPLES

Our refractory materials are widely used in various aluminum smelting enterprises, providing reliable protection for production facilities of any scale and technological processes.

Large Aluminum Smelting Enterprises

We provide comprehensive refractory solutions for large aluminum smelting enterprises with over 100,000 tons annual capacity. Our products meet stringent durability and stability requirements for large-scale production environments.

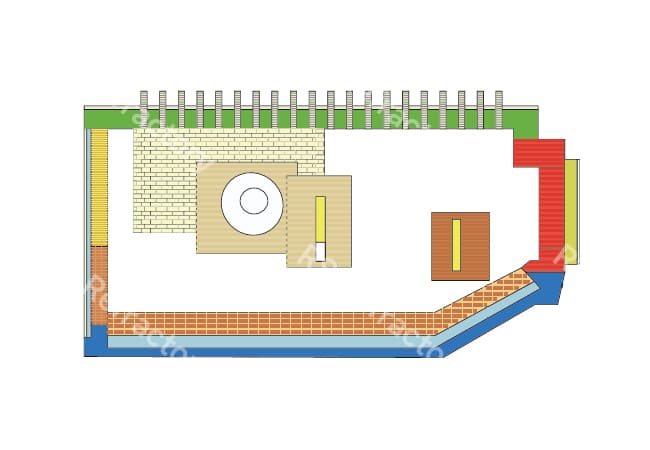

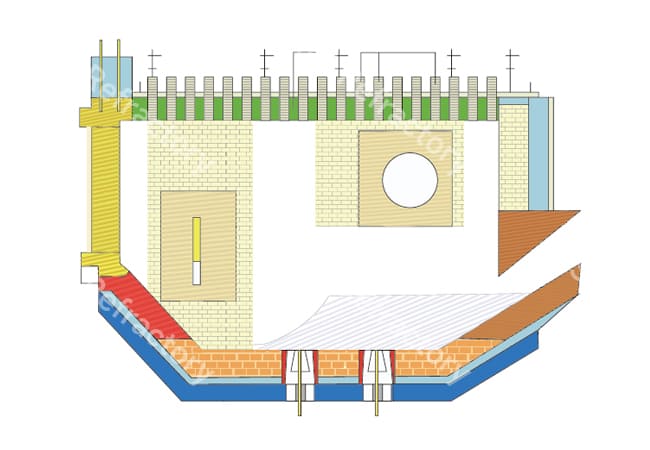

Refractory Installation for Large Aluminum Holding Furnaces

For large aluminum holding furnaces, choosing us means embracing an engineering philosophy centered on technology and long-term reliability. We deliver not just a simple installation project, but an efficient, stable, and energy-saving modern production tool.

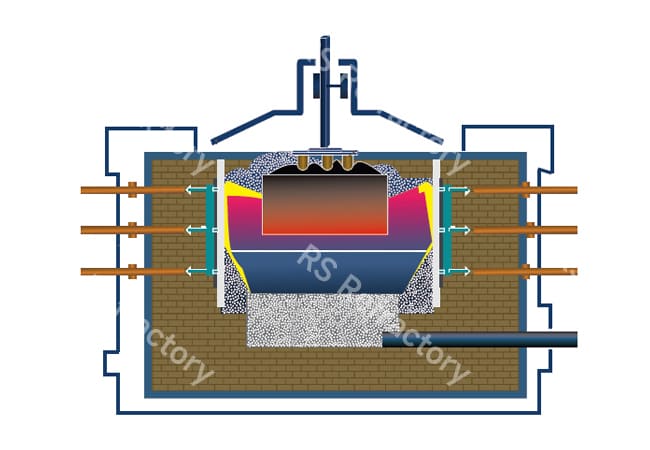

Installation of Silicon Carbide Bricks for 600kA Prebaked Cells

Our self-developed high-thermal-conductivity reaction-sintered silicon carbide bricks are adopted, effectively blocking electrolyte penetration and reducing replacement frequency and maintenance costs caused by corrosion.