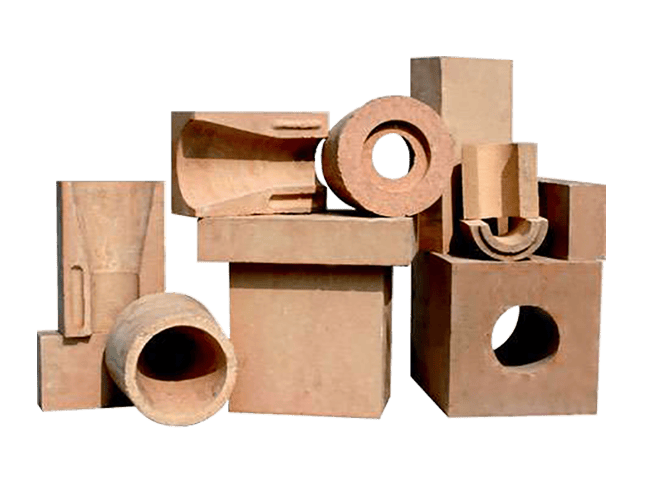

Zircon-mullite Brick

ZrO₂ content: 6/12/20/30%, expert-level corrosion resistance, extremely long service life

Application

High-temperature corrosion protection for aggressive zones of industrial furnaces: for glass melting furnaces (melting tanks, regenerators, etc.), metallurgical furnaces, waste incinerators and hazardous waste processing units, as well as hearths of heating furnaces and discharge troughs of rolling mills.”

Specifications

|

Item |

ZM-6 |

ZM-12 |

ZM-20 |

ZM-30 |

|---|---|---|---|---|

|

ZrO2 % |

≥6 |

≥12 |

≥20 |

≥30 |

|

Al2O3 % |

≥65 |

≥55 |

≥55 |

≥50 |

|

Fe2O3 % |

≤0.2 |

≤0.2 |

≤0.2 |

≤0.2 |

|

Bulk Density g/cm3 |

≥2.8 |

≥2.9 |

≥2.95 |

≥3.0 |

|

Open Porosity % |

≤17 |

≤17 |

≤17 |

≤17 |

|

Cold Crushing Strength MPa |

≥80 |

≥80 |

≥80 |

≥80 |

|

Refractoriness Under Load (Т0,6), °C |

≥1680 |

≥1680 |

≥1680 |

≥1680 |

Features

Ultra-high thermal resistance

Long-term operating temperature up to 1600°C, short-term resistance up to 1800°C without softening, 40% higher thermal resistance compared to traditional high-alumina bricks.

Exceptional corrosion resistance

Superior resistance to acidic/alkaline slags and glass melt, HCl resistance 3 times higher than high-alumina brick.

Durability

Service life 3 times higher (or 2 times longer) than traditional materials.

Applications

Glass Melting Furnaces

High-Abrasion Zone Applications: Coolers, Checkerwork, Crowns, Hearth Blocks, Inspection Window, Burner Blocks

Glass Melting Furnaces

Glass Melt Contact Zones: Melting Tank, Hot Spot Areas

Metallurgical Furnaces

Critical Components of High-Temperature Smelting & Heating Furnaces

Hazardous Waste Incineration Systems

Corrosion Resistance + Thermal Stability → 2-3x Extended Service Life