Andalusite bricks

Material: Andalusite, sillimanite, mullite, microsilica, clay Advantage: Low creep rate Category: Alumina-Silicate Refractories Al2O3-SiO2

Application

Lining of industrial furnaces and heat engineering equipment with sharp temperature fluctuations

Specifications

| Item | RH155 | RH150 | RH145 | RH140 | RH135 |

|---|---|---|---|---|---|

| Al2O3 % | ≥69 | ≥65 | ≥61 | ≥57 | ≥53 |

| Fe2O3 % | ≤1.0 | ≤1.0 | ≤1.2 | ≤1.2 | ≤1.5 |

| TiO2 % | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.6 | ≤0.6 |

| Open Porosity % | ≤20 | ≤20 | ≤20 | ≤20 | ≤20 |

| Bulk Density g/cm3 | 2.55~2.70 | 2.50~2.65 | 2.45~2.60 | 2.40~2.55 | 2.35~2.50 |

| Cold Crushing Strength MPa | ≥55 | ≥55 | ≥50 | ≥50 | ≥40 |

| Refractoriness Under Load 0,2 MPa °C | ≥1700 | ≥1700 | ≥1650 | ≥1600 | ≥1520 |

| Linear Change on Reheating % | 1500°C×2h ±0.2 | 1500°C×2h ±0.2 | 1500°C×2h ±0.2 | 1450°C×2h ±0.2 | 1450°C×2h ±0.2 |

| Creep Rate % 0.2 MPa 0~50h | ≤0.8 1550°C | ≤0.8 1500°C | ≤0.8 1450°C | ≤0.8 1400°C | ≤0.8 1350°C |

Features

Andalusite alumina bricks have a minimum content of impurities, which ensures a slight decrease in strength at high temperatures. It has high temperature resistance, mechanical strength, thermal shock resistance, slag resistance, increased softening point under load, as well as exceptional chemical stability and corrosion resistance. Andalusite begins to transform into needle-like mullite when heated to 1350°C under normal conditions. Mullite crystals are the only thermodynamically stable form of aluminosilicates at high temperatures.

| Parameter | Andalusite bricks | Традиционные огнеупоры |

|---|---|---|

| Creep Rate (1500°C) | ≤0.8%/h | 0.8-1.2%/h |

| Porosity | 12-15% | 18-22% |

| Refractoriness Under Load | 1520-1700°C | 1550-1650°C |

Applications

Andalusite brick has a dense homogeneous monolithic structure without slag channels, which makes it an ideal refractory material for lining steelmaking furnaces, resistant to slag corrosion and penetration. Due to its low content of fusible oxides (<0.8%) it is not prone to premature softening, maintaining long term performance at high temperatures.

Key Applications:

Metallurgy:

- Blast furnace and air heater linings: Service life increased by 40-60%

- Nozzle materials for steel ladles

- Internal linings for torpedo ladles (40-60% service life increase)

Other Industries:

- Rotary cement kilns (sintering zone)

- Tunnel ceramic kilns (firing chambers)

- Glass furnaces (alkali contact areas)

- Roasting Furnace

- Critical areas: Domes, cones, tuyere devices

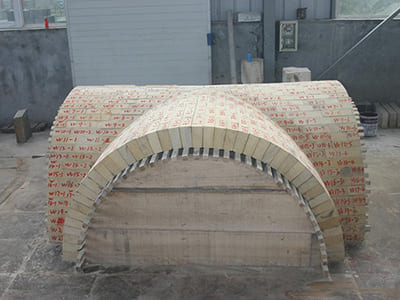

Pre-laying of hot blast stove vents

Pre-laying of hot blast stove vents