RS Refractory

Production

RS Refractory specializes in manufacturing high-quality refractory products and integrated solutions for the global high-temperature industry. With stringent quality standards, advanced installation technologies, and customer-oriented service, RS has earned the trust of leading enterprises in the glass, metallurgical, energy, and petrochemical industries.

RS Refractory’s Facilities:

- 3 R&D Centers (focusing on material innovation and application technology)

- 2 Education-Science-Production” Bases (collaboration with universities)

- Production Base for Shaped Refractories (annual capacity: 80,000 tons)

- 2 Production Bases for Unshaped Refractories (total annual capacity: 150,000 tons)

Shaped Refractories Production

Production Resource Configuration:

- 1 R&D Center (dedicated to refractory material optimization)

- 2 Education-Science-Production” Bases (joint projects with academic institutions)

- Engineering & Design Office (custom refractory solutions)

- Refractory Quality Control Lab (ensuring compliance with GB/T, ASTM, ISO)

- 2 Tunnel Kilns, 2 High-Temperature Shuttle Kilns

- 11 Presses, Henan Province’s Most Powerful Press (12,500 kN force, ideal for high-density bricks and large precast shapes)

Production of Monolithic Refractories

Manufacturing Resource Configuration:

- 2 R&D Centers

- 2 Production Facilities

- Engineering Design Bureau

- Quality Control Laboratory

- Crushing, Mixing, Storage: 3,500-ton capacity silos

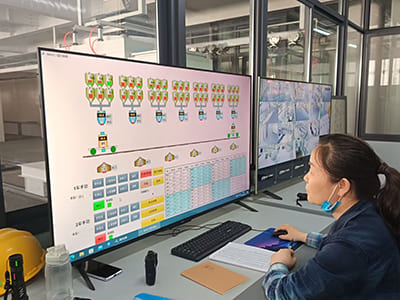

- Automated Batching System

Manufacturing Process of Shaped Refractories

Complete Production Flow from Raw Materials to Finished Products

4.Mixing

3.Screening/Grading

2.Crushing

1.Raw Material Selection

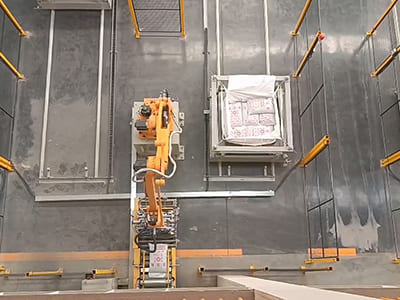

5.Forming

6.Drying

7.Firing

8.Visual Inspection

12.Dispatch

11.Storage

10.Packaging

9.Testing

Production Process of Monolithic (Unshaped) Refractories

Complete Production Flow from Raw Materials to Finished Products

4.Transport Cart

3.Screening/Grading

2.Crushing

1.Raw Material Selection

5.Mixing

6.Numerical Program Control

7.Test Samples

8.Testing

12.Dispatch

11.Storage

10.Packaging

9.AI-Packaging System