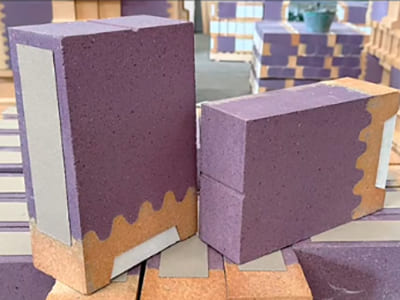

Chrome-Alumina-Zirconia Refractories

Cr2O3-ZrO₂-Al₂O₃ brick (Chrome Zirconia Corundum Brick). By incorporating zirconium oxide into a chrome corundum matrix, this product develops a network of sealed micropores and microcracks during high-temperature service. This microstructure enhances its mechanical strength, abrasion resistance, slag erosion resistance, and thermal shock (spalling) resistance.

Application

Glass Melting Furnace; Hazardous Waste Incinerator

Specifications

| Item | GGZ-75 | GGZ-85 | GGZ-90 | GGZ-95 |

|---|---|---|---|---|

| Cr2O3 % | ≥75 | ≥85 | ≥90 | ≥95 |

| Cr2O3+Al2O3+ZrO2 % | ≥98 | ≥98 | ≥98 | ≥98 |

| SiO2 % | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 |

| Fe2O3 % | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 |

| K2O+Na2O % | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 |

| Open Porosity % | ≤18 | ≤18 | ≤16 | ≤16 |

| Bulk Density g/cm³ | ≥3.90 | ≥4.2 | ≥4.22 | ≥4.25 |

| Cold Crushing Strength MPa | ≥120 | ≥120 | ≥120 | ≥120 |

| Composition is optimized according to the customer’s technological conditions. Dimensions are executed based on individual parameters. | ||||

Features

Excellent Wear Resistance

Capable of resisting abrasive material impact in critical zones.Exceptional Corrosion Resistance

Enhanced resistance to molten glass and corrosive attack by aggressive meltsHigh Thermal Resistance

Suitable for use at temperatures up to 1700°CApplications

- Hazardous Waste Incinerator

- Glass Melting Furnaces for Soda-Lime-Silica Glass

- Non-Ferrous Metallurgical Smelting Furnaces

Regenerator Checkerwork for Glass Melting Furnace

Carbon Black Production Furnace Masonry

Rotary Kiln for Hazardous Waste

Steel Teeming Trough

Walking Beam Furnace Hearth Beams