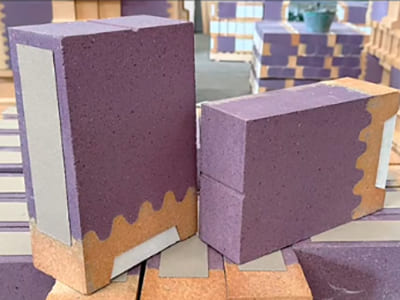

Chrome Corundum Brick

Chromium corundum products exhibit superior high-temperature performance compared to pure corundum products.

Application

Suitable for glass melting furnaces, steelmaking metallurgical furnaces, copper smelting furnaces, aluminum electrolysis cells, rotary kilns, and high-temperature reactors.

Description

Chrome corundum bricks are produced using chromium oxide and aluminum-containing components as raw materials. These are mixed in specific proportions and melted at temperatures exceeding 2000°C to form chrome corundum clinker, with aluminum-chromium solid solution as the primary crystalline phase. The clinker is then crushed, batched, mechanically pressed, and fired at high temperature to obtain the final brick products.

Specifications

| Item | GGZ-5 | GGZ-12 | GGZ-20 | GGZ-30 |

|---|---|---|---|---|

| Cr2O3 % | ≥5 | ≥12 | ≥20 | ≥30 |

| Cr2O3+Al2O3 % | ≥93 | ≥93 | ≥93 | ≥93 |

| Fe2O3 % | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 |

| Apparent Porosity % | ≤18 | ≤18 | ≤18 | ≤18 |

| Bulk Density g/cm³ | ≥3.10 | ≥3.20 | ≥3.40 | ≥3.50 |

| Cold Crushing Strength MPa | ≥100 | ≥100 | ≥100 | ≥100 |

| Refractoriness Under Load (0.2 MPa) °C | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

| Composition optimized based on client’s operating conditions Dimensions customized to personalized parameters | ||||

Features

Erosion Resistance

Possesses excellent resistance to erosion by steelmaking slag, non-ferrous metallurgical slag, coal gasification slag, and various types of molten glass.Easy Installation

The ratio of coarse, medium, and fine aggregates as well as powder can be adjusted according to requirements. It can be used simply by adding a binder and an accelerator.Excellent High-Temperature Resistance

Withstands temperatures up to 1700°C, making it suitable for extreme high-temperature and corrosive environments.Applications

-

-

- Glass Melting Furnace: Lining for melting pool working layer and protective layer

- Cement Kiln

- Ferrous Metallurgy: Furnace lining, walls, and roofs for blast furnaces, electric arc steelmaking furnaces, converters, and other steelmaking equipment

- Non-Ferrous Metallurgy: Lining for electrolytic cells, converters, and smelting furnaces

- Hazardous Waste Incinerators

- Waste Incineration Furnaces

- Carbon Black Production Reactors

- Coal-Water Slurry Gasifiers

-

Regenerator Checkerwork for Glass Melting Furnaces

Carbon Black Reactor Masonry

Hazardous Waste Rotary Kiln

Ladle Trough / Steel Pouring Trough

Walking Beam Furnace Hearth Beam