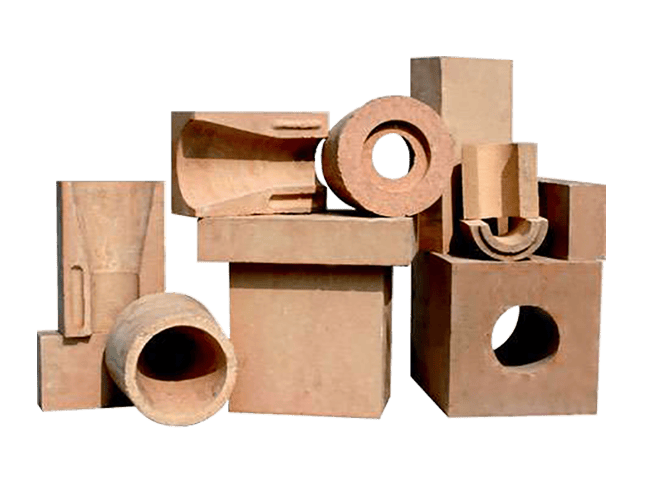

Zirconium corundum brick

Material: High-purity alumina (Al₂O₃); zircon (ZrSiO₄); desilicated zirconia (baddeleyite) Phases: Corundum + baddeleyite + glass phase Properties: Resistance to glass corrosion, no glass contamination (AZS bricks)

Application

Glass melting furnaces, electric furnaces, steel teeming gates, sodium silicate kilns, aluminum electrolytic cells, quartz melting furnaces, and phosphate furnaces.

Description

Fused cast zirconia-corundum bricks are produced by melting the following raw materials in an electric furnace:

- High-purity alumina powder (Al₂O₃)

- Zircon sand (ZrSiO₄)

- Desilicated zirconia (ZrO₂)

- Bakor

- Bakor products

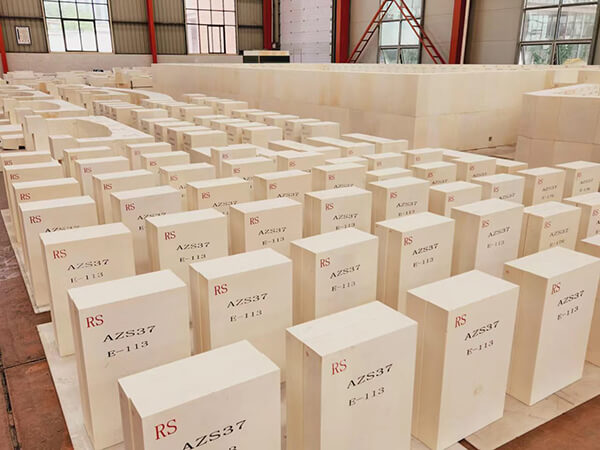

- Fused cast AZS bricks

- AZS refractory

- Fused AZS refractory bricks

The abbreviation AZS comes from the Al₂O₃-ZrO₂-SiO₂ ternary system, where the chemical components are denoted by their initials in descending order of content:

- Al₂O₃ (alumina) = A

- ZrO₂ (zirconia) = Z

- SiO₂ (silica) = S

- AZS-41 or BK-41 (indicating a fused zirconia-corundum brick with 41% ZrO₂ content)

Classification

Classification by ZrO₂ Content

- AZS-33/БК-33: 33% ZrO₂

- AZS-36/БК-36: 36% ZrO₂

- AZS-41/БК-41: 41% ZrO₂

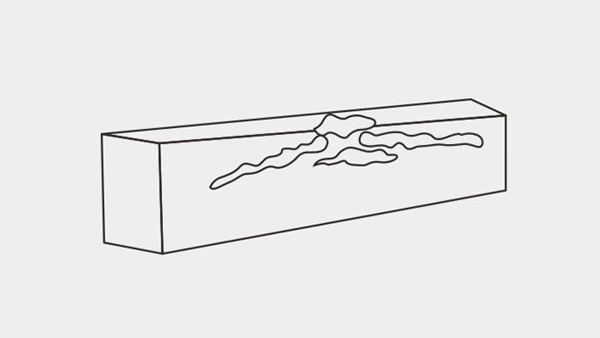

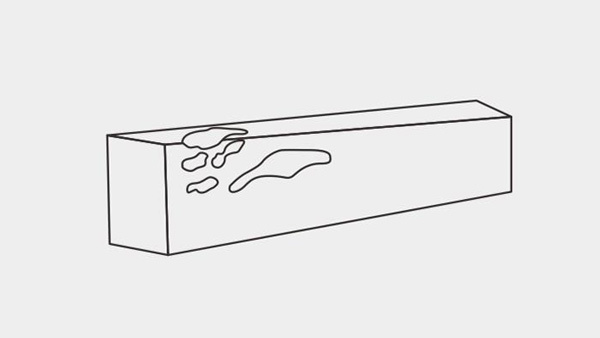

Classification by Casting Method

- NC: Normal Cavity

- OC: Oriented Cavity

- RC: Reduced Cavity

- FC: Full cut Cavity

NC

In the upper zones of melting basins (where there is no direct contact with molten glass).

OC

For products with a length >60 mm and for manufacturing sidewall bricks of glass melting furnaces.

RC

As sidewall bricks for glass melting furnaces

FC

Highly corrosion-stressed areas: Throat areas (outlet holes), Furnace thresholds (weirs), Corner zones of melting basin, Lining of working surfaces (directly exposed to molten glass)

Specifications

| Brand | NC | OC | RC | FC | |

|---|---|---|---|---|---|

| БК-33/AZS-33 | Bulk Density g/cm3 | ≥3.55 | ≥3.65 | ≥3.65 | ≥3.75 |

| БК-36/AZS-36 | Bulk Density g/cm3 | ≥3.55 | ≥3.75 | ≥3.75 | ≥3.85 |

| БК-41/AZS-41 | Bulk Density g/cm3 | ≥3.7 | ≥3.9 | ≥3.85 | ≥3.95 |

| Item | БК-33/AZS-33 | БК-36/AZS-36 | БК-41/AZS-41 |

|---|---|---|---|

| Al2O3, % | ≥50.00 | ≥49.00 | ≥45.00 |

| ZrO2, % | ≥32.50 | ≥35.50 | ≥40.50 |

| SiO2, % | ≤15.00 | ≤13.50 | ≤12.50 |

| Na2O+K2O, % | ≤1.30 | ≤1.35 | ≤1.3 |

| Bulk Density g/cm3 | ≥3.75 | ≥3.85 | ≥4 |

| Apparent Porosity % | ≤1.2 | ≤1.0 | ≤1.2 |

| Cold Crushing Strength MPa | ≥200 | ≥200 | ≥200 |

| Glass phase exudation temperature °С | ≥1400 | ≥1400 | ≥1410 |

| Bubble Evolution Rate 1300°С×10h | ≤1.2 | ≤1.0 | ≤1.0 |

| Static Corrosion Rate by Molten Glass 1500°С×36h (mm/24 h)% | ≤1.4 | ≤1.3 | ≤1.2 |

Applications

AZS-33/BK-33 products exhibit exceptional resistance to glass melt contamination, minimizing the formation of:

- Stones (crystalline inclusions)

- Gas bubbles

- Phase separation in the glass matrix

- Upper structures of melting tank

- Gas space (flame zone)

- Furnace crown

- Sidewall bricks and working lining

- Batch charging channels

AZS-36/BK-36 products feature the following key characteristics:

- High resistance to corrosive action of glass melt

- Minimal contaminating effect

- Optimal balance of these properties

- Sidewall bricks of melting tank

- Threshold blocks (thermal barriers)

- Charging pocket (batch feeding zone)

- Other highly stressed areas

AZS-41/BK-41 is a high-performance product in the fused AZS material series, featuring exceptional properties:

- Extreme resistance to glass melt corrosion

- Record-high glass phase exudation temperature

- Minimal contaminating effect on glass melt

- Sidewall bricks in maximum temperature zones (hot spot)

- Corner areas of charging pocket

- Throat area (outlet hole)

- Furnace threshold (thermal barrier)

- Bottom bubbling zone

- Electrode blocks and transition bricks in all-electric furnaces

Photos

Related Products