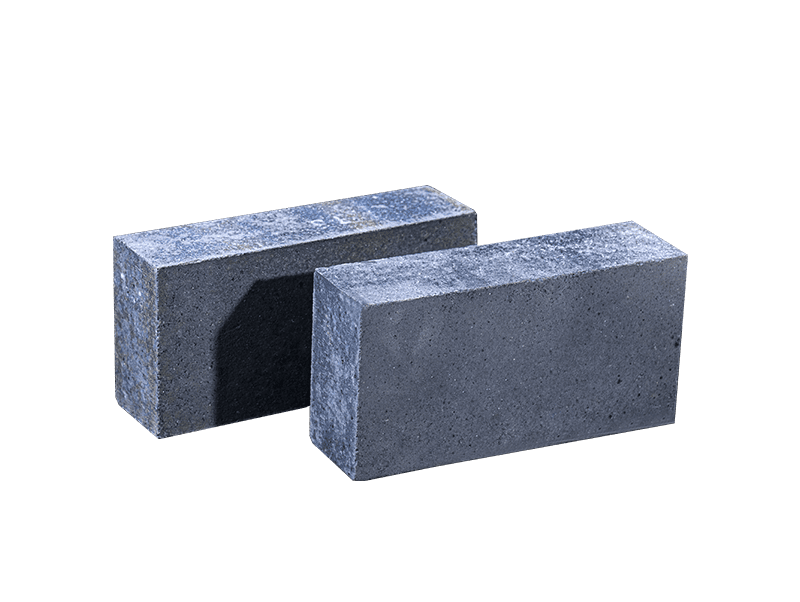

Silicon carbide bricks

Mohs hardness of 9. High resistance to acidic slags.

Application

Designed for furnaces used in non-ferrous metal smelting, aluminum casting molds, electric furnaces, waste incinerators, blast furnaces, and zinc distillation kettles.

Description

Silicon Carbide (Carborundum) Bricks are refractory materials primarily composed of SiC (72–99% content). Classification by Bonding Type: 1. Clay-bonded (with added fireclay) 2. Si₃N₄-bonded (silicon nitride) 3. Sialon-bonded (Si₆-zAlzOzN₈-z) 4. β-SiC-bonded (nano silicon carbide particles) 5. Oxynitride-bonded (Si₂ON₂) 6. Recrystallized (bond-free, sintered at >2200°C)Specifications

| Item | Bonding Type | |||||

|---|---|---|---|---|---|---|

| SiO2 | Clay | Si3N4 | Sialon | β-SiC | Recrystal-SiC | |

| SiC % | 90 | ≥85 | ≥75 | ≥70 | 94 | ≥99 |

| SiO2 % | 10 | 6~10 | / | / | 3.0 | / |

| Si3N4 % | / | / | ≥20 | / | / | / |

| Sialon % | / | / | / | ≥20 | / | / |

| Bulk Density, g/cm3 | 2.6~2.7 | 2.5~2.6 | 2.6~2.66 | 2.7 | 2.63 | 2.6~2.8 |

| Apparent Porosity, % | 12~15 | 14~20 | 19 | 15 | 16 | 7~20 |

| CCS, MPa | 100~145 | 100~160 | 220 | 228 | 140 | / |

| CMOR, MPa | 25 | 20~25 | 45 | 50 | 30~50 | 70~100 |

| Thermal Expansion Rate, ×10-6/°C | 4.7 | 4.6 | 4.6 | 5.1 | 5.5 | 4.5~5 |

| Thermal Conductivity, W/(m·K) 1000°C | 11~14.5 | 11~14 | 15 | 17.4 | 12.8 | 28 |

Features

Excellent thermal conductivity

Rapid heat transfer capabilityAbrasion Wear Resistance

Mohs hardness of 9 – second only to diamond (10)High Thermal Shock Resistance

Low Coefficient of Thermal ExpansionApplications

- Ceramic Industry: Shelving plates, posts, saggars

- Metallurgy: Ladle linings, tundish nozzles, stopper rods

- Blast Furnaces: Hearth linings, tuyere coolers, tuyeres, cooling staves, tap holes

- Non-Ferrous Metallurgy: Zinc distillation kettles; aluminum electrolytic cell linings

- Heating Furnaces: For Steel Slab Reheating

- Chemical Industry: Lining Plates and Thermal Insulation Partitions for High-Temperature Reactors

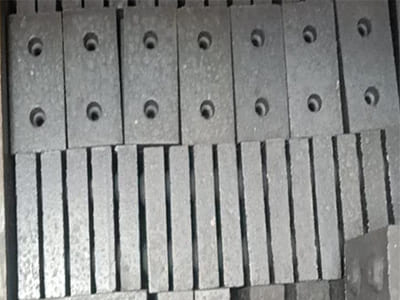

Blast Furnace Tuyere Products

For Blast Furnace Cooling Plates

Refractory Plates for Silicate Industry Furnaces

Silicon Carbide Products for Pyrolysis Furnaces

Silicon Nitride Bonded Silicon Carbide Brick for Waste Incineration Furnaces