Zirconia Brick

Silicon- and sodium-free. With a sustained operating temperature of up to 2000°C, this product demonstrates significant advantages in contact with sodium-based, boron-containing, lead-based, and fluoride glasses, as well as in high electrical resistivity environments. Under comparable service conditions above 1550°C, its service life exceeds that of AZS materials (fused cast alumina-zirconia-silica refractory) by more than 3 times.

Application

Glass Melting Furnace; Fiberglass Forming Device; Anhydrous Borax Furnace

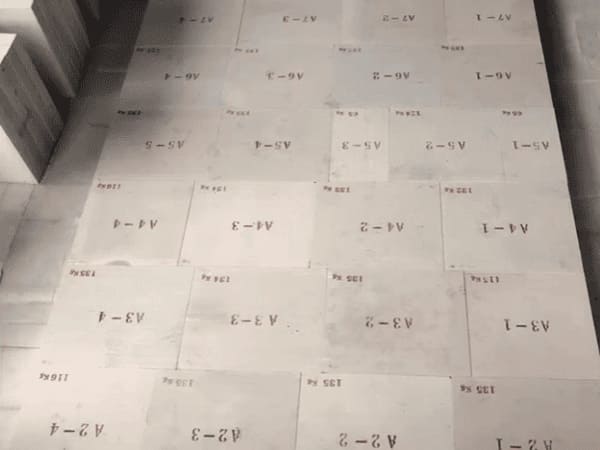

Specifications

| Item | GZ-93 |

|---|---|

| ZrO2 % | ≥93 |

| SiO2 % | ≤5 |

| Al2O3+TiO2+Fe2O3+K2O+Na2O % | ≤2.0 |

| Bulk Density g/cm3 | ≥5.3 |

| Cold Crushing Strength MPa | ≥400 |

| Refractoriness under Load 0.2MPa °C | ≥1700 |

| Composition is optimized according to the client’s process conditions, and dimensions are customized to individual parameters. | |

Features

Long Service Life

Lasts 3x Longer Than Conventional AZS Refractories.Exceptional Corrosion Resistance

Free of silicon and sodium. Does not contaminate the glass, ensuring its purity.High Thermal Stability

Usable at temperatures up to 2000°CApplications

- Photovoltaic Glass Furnace: roller lip, channel block, feeder nozzle, stirrer, stirrer blade, plunger, and others.

- Extended Campaign Glass Melting Furnace: basin wall, rotary drum, hot repair masonry zone (with brick anchoring system).

- Extended Campaign Glass Melting Furnace: basin wall, furnace bottom, electrode port, forehearth channel.

- Sapphire Crystal Growth Furnace.

- Fused Quartz Glass Melting Furnace.

- Optical Fiber Drawing Furnace.

- Hard Alloy / Cemented Carbide Melting Furnace.

- Insulation Materials for Lids and Other Components of Ultra-High Temperature Equipment: medium frequency induction furnaces, carbon black production reactor, tungsten furnace, molybdenum furnace.