Refractories for Aluminum Melting Furnaces

High-performance refractory solutions specifically developed for aluminum melting furnaces. They possess excellent thermal resistance, corrosion resistance to molten aluminum, and thermal stability, meeting various aluminum smelting process requirements.

Working temperature: 1200-1600°C Corrosion resistance to molten aluminum Excellent thermal shock resistance Extended furnace service life

PRODUCT OVERVIEW

Aluminum melting furnaces are key equipment in aluminum smelting and processing, used to heat solid aluminum to a molten state. Due to extreme operating conditions—including high temperatures, corrosive molten aluminum exposure, and frequent thermal fluctuations—refractories must meet exceptionally high requirements.

Our specialized refractory series for aluminum melting furnaces is manufactured from high-quality raw materials using advanced technology. Years of practical application have confirmed their ability to provide reliable lining solutions for all types of aluminum melting furnaces. Whether for continuous or batch furnaces, primary aluminum production or secondary material processing, we offer targeted product selection.

This product series not only delivers excellent thermal resistance but also effectively withstands corrosion from molten aluminum, slags, and various additives. Simultaneously, it ensures outstanding thermal stability, enabling resistance to frequent temperature fluctuations, significantly extending furnace service life, and reducing operational costs and downtime.

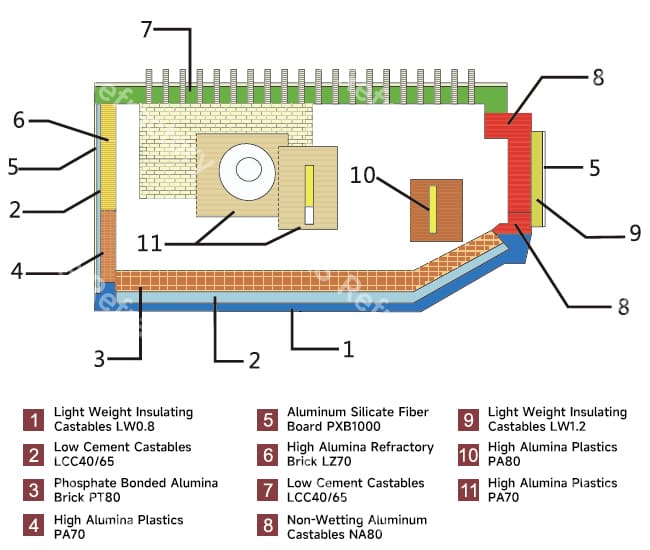

PRODUCT TYPES

We offer a wide range of specialized refractories for aluminum melting furnaces, designed for various zones and technological processes.

![]()

LW0.8/1.0/1.2

PA70

door frame, door lintel LCC-40/65

measurement holes, aluminum tap holes, door frames, and lintels NA80

APPLICATION EXAMPLES

Our refractory materials are widely used in various aluminum smelting enterprises, providing reliable protection for production facilities of any scale and technological processes.

LARGE ALUMINUM SMELTING ENTERPRISES

We provide comprehensive refractory material solutions for large aluminum smelting enterprises with an annual production capacity exceeding 100,000 tons. Our products meet the stringent requirements for durability and stability of refractories in large-scale production environments.

SECONDARY ALUMINUM RECYCLING ENTERPRISES

We offer specialized refractories with enhanced resistance to impurity impacts, specifically adapted for secondary aluminum recycling processes. Our products are engineered to perform under conditions involving frequent charge loading and significant temperature fluctuations.

ALUMINUM PROCESSING AND CASTING WORKSHOPS

We provide comprehensive customized refractory solutions for diverse melting and heat-holding units in aluminum processing and casting workshops. We guarantee consistent stable molten aluminum quality, enhanced high production efficiency, and significant energy conservation performance.

PRODUCT ADVANTAGES

Our specialized refractories for aluminum melting furnaces offer significant advantages over comparable products

Extended Service Life

The use of high-quality raw materials and advanced technologies increases service life by 30-50% compared to standard products, reducing replacement frequency and downtime.

Exceptional Corrosion Resistance

Specially developed formulations provide exceptional resistance to molten aluminum, slags, and chemical additives, ensuring furnace structural integrity.

High Thermal Stability

Withstands extreme and rapid temperature fluctuations, maintaining structural integrity and functionality during frequent heating and cooling cycles without cracking or deformation.

Reduced Total Cost of Ownership

Despite slightly higher initial investments, the total cost is reduced by 20-40% due to extended service life and lower maintenance expenses.

TECHNICAL SUPPORT AND SERVICE

We provide a full range of technical support and services to ensure optimal product performance

Customized Solution Design

We develop tailored refractory selections and optimized lining schemes based on customer furnace type, specifications, technological features, and operating conditions.

On-Site Technical Guidance

We dispatch professional technical personnel to ensure strict installation control, guarantee construction quality, and optimize refractory performance.

After-Sales Service

We conduct regular furnace inspections and audits, providing maintenance recommendations and repair solutions to extend equipment service life.