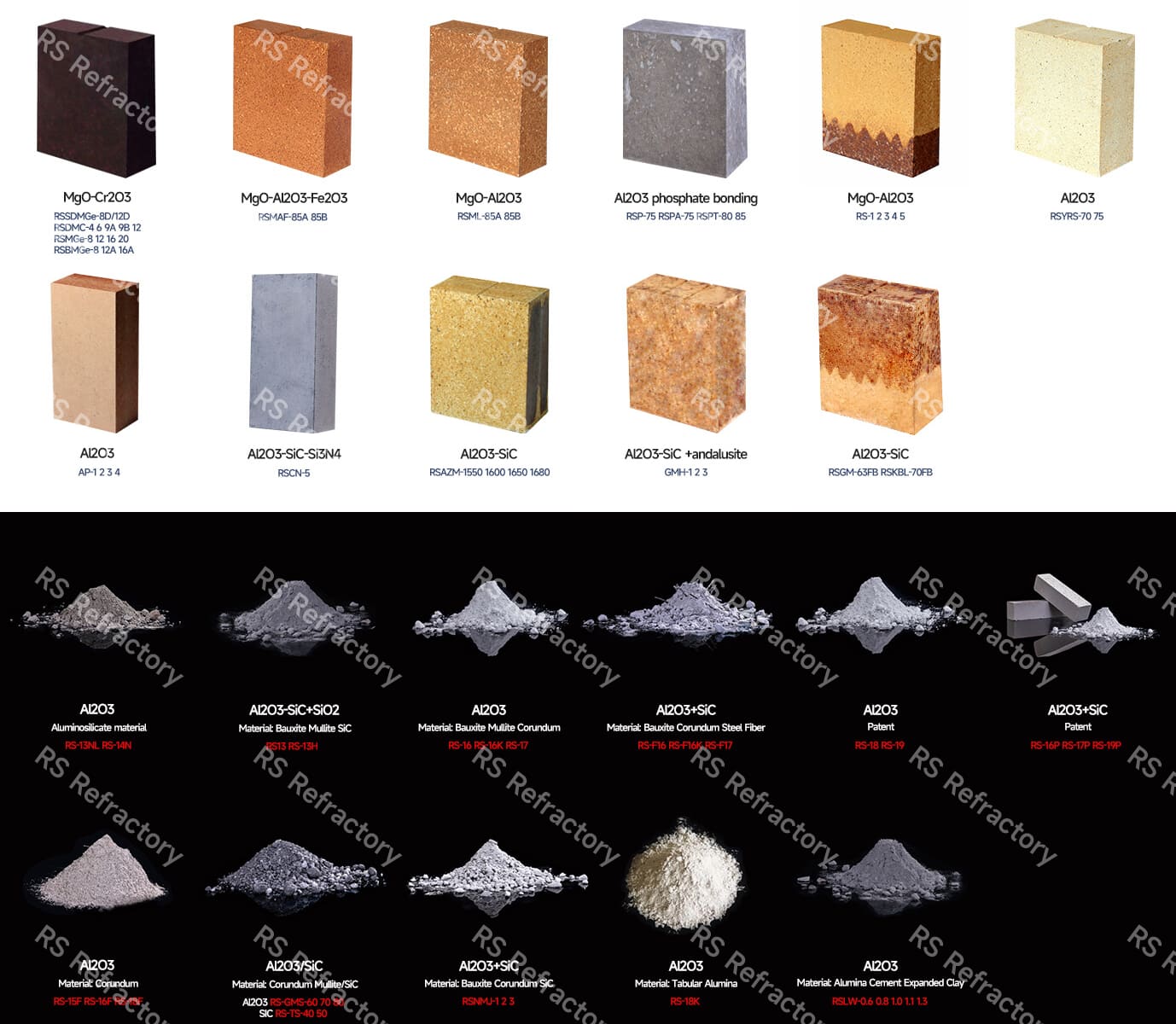

Classification by technological generation

With the development of the cement industry, refractory materials used in cement kilns have also undergone multiple generations of technological innovation, with each generation of products targeting specific industry needs and technical challenges.

Wet rotary kiln

Sections

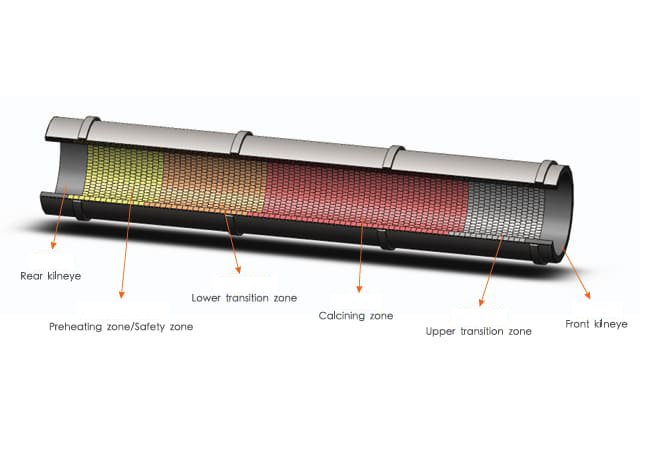

| Rear kilneye | Aluminum LCC RS-16 |

| Preheating zone/Safety zone | High strength alkali proof brick |

| Lower transition zone | Phosphate bonded wear-resistant brick RSPA-75 |

| Calcining zone | Special phosphate brick RSPT-1 |

| Upper transition zone | Phosphate bonded wear-resistant brick RSPA-75 |

| Front kilneye | Steel Fibre Reinforced Refractory Castable RS-F16 |

700-3000t/d rotary kiln

Sections

| Rear kilneye | Steel Fibre Reinforced Refractory Castable RS-F16K |

| Preheating zone/Safety zone | Anfi-strip alumina brick RSYRS-70 |

| Lower transition zone | Silicon mullite brick RSAZM-1680 |

| Calcining zone | Direct bonded magnesia-chrome brick RSDMC-8A |

| Upper transition zone | Composite carbon and nitrogen brick RSCN-5 |

| Front kilneye | Steel Fibre Reinforced Refractory Castable RS-F17 |

3000-10000t/d rotary kiln

Sections

| Rear kilneye | Special castable for kilneye RS-19 |

| Preheating zone/Safety zone | Silicon mullite brick RSAZM-1650 |

| Lower transition zone | Magnesium aluminum spinel brick RSML-85A |

| Calcining zone | Magnesium aluminum iron composite spinel brick RSMAF-85A |

| Upper transition zone | Magnesium aluminum spinel brick RSML-85A |

| Front kilneye | Special castable for kilneye RS-19 |

Classification by kiln type

Different types of cement kilns have different requirements for refractory materials. Selecting the appropriate refractory materials based on the characteristics of the kiln type is key to ensuring production efficiency.

Refractories for traditional cement kiln

Wet-process cement kilns, featuring high moisture content in raw slurry, elevated thermal energy demand, and longer kiln bodies, necessitate refractory linings with enhanced corrosion resistance and superior insulating performance.

Under normal load condition

Sections

| Rotary kiln | Rear kilneye | Special castable for kilneye RS-18 RS-19 |

| Drying zone | Ordinary alkali resistant brick | |

| Preheating zone | High strength alkali proof brick | |

| Lower transition zone | Phosphate bonded wear-resistant brick RSPA-75 | |

| Calcining zone | Special phosphate brick RSPT-1 | |

| Upper transition zone | Phosphate bonded wear-resistant brick RSPA-75 | |

| Front kilneye | Specical castable for kilneye RS-18 RS-19 | |

| Burner | Coal bruner castable RS-16P RS-17P | |

| Grate cooler | Mulite LCC RS-16K | |

Under severe load condition

Sections

| Rotary kiln | Rear kilneye | Tabular corundum castable RS-18K |

| Drying zone | High strength alkali resistant brick | |

| Preheating zone | Ant-strip alumina brick RSYRS-70 | |

| Lower transition zone | Silicon mullite brick RSAZM-1650 | |

| Calcining zone | Direct bonded magnesia-chrome brick RSDMC-4 RSDMC-6 | |

| Upper transition zone | Silicon mullite brick RSAZM-1650 | |

| Front kilneye | Tabular corundum castable RS-18K | |

| Burner | Coal burner castable RS-19P | |

| Grate cooler | Mulite LCC RS-16K | |

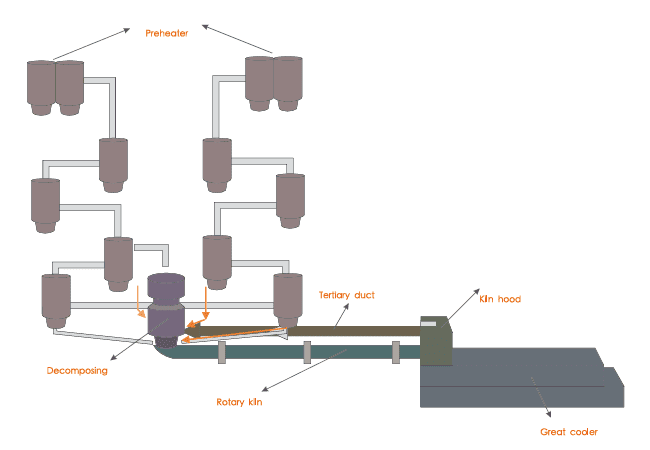

Refractories for the new dry-process cement rotary kiln

Modern dry-process cement kilns are characterized by high production capacity, superior thermal efficiency, and advanced automation. Refractory configurations vary significantly based on kiln throughput capacity.

| Sections | 6000-10000t/d | 3000-6000t/d | 2000-3000t/d | 700-2000t/d |

|---|---|---|---|---|

| Preheater | High-strength alkali-resistant castable RS-14N Anticaking castable RS-13H Vaulted alkali proof brick |

High-strength alkali-resistant castable RS-13NL Anticaking castable RS-13 High strength alkali proof brick |

High-strength alkali-resistant castable RS-13NL Anticaking castable RS-13 High strength alkali proof brick |

High-strength alkali-resistant castable RS-13NL Anticaking castable RS-13 General type alkali proof brick |

| Decomposing furnace | Aluminum LCC RS-16 Antistrip alumina brick RSYRS-70 |

Aluminum LCC RS-16 Antistrip alumina brick RSYRS-70 |

High-strength alkali-resistant castable RS-13NL Antistrip alumina brick RSYRS-75 |

High-strength alkali-resistant castable RS-13NL Vaulted akali proof brick |

| Tertiary duct | Tertiary duct castable RS-18F Silicon mullite brick RSAZM1550 |

Tertiary duct castable RS-18F Silicon mullite brick RSAZM1550 |

Tertiary duct castable RS-16F High strength alkali proof brick |

Tertiary duct castable RS-15F High strength alkali proof brick |

| Rear kilneye | Special castable for kilneye RS-19 Tabular corundum castable RS-18K |

Special castable for kilneye RS-19 Tabular corundum castable RS-18K |

Special castable for kilneye RS-18 Steel Fibre Reinforced Refractory Castable RS-F17 RS-F16K |

Special castable for kilneye RS-18 Steel Fibre Reinforced Refractory Castable RS-F16 |

| Safety zone | Silicon mullite brick RSAZM1650 | Silicon mullite brick RSAZM1550 Antistrip alumina brick RSYRS-70 |

Antistrip alumina brick RSYRS-70 | Antistrip alumina brick RSYRS-70 |

| Lower transition zone | Magnesium aluminum spinel brick RSML-85A Silicon mullite brick RSAZM1680 |

Magnesium aluminum spinel brick RSML-85B Silicon mullite brick RSAZM-1680 RSAZM-1650 |

Silicon mullite brick RSAZM-1680 RSAZM-1650 | Silicon mullite brick RSAZM-1650 |

| Calcining zone | Magnesium aluminum iron composite spinel brick RSMAF-85A | Magnesium aluminum iron composite spinel brick RSMAF-85B | Direct bonded magnesia-chrome brick RSDMC-8A RSDMC-8B Magnesium aluminum iron composite spinel brick RSMAF-85B |

Direct bonded magnesia-chrome brick RSDMC-4 RSDMC-6 Semi-bonded magnesia-chrome brick RSSDMGe-8D |

| Upper transition zone | Magnesium aluminum spinel brick RSML-85A Composite carbon and nitrogen brick RSCN-5 |

Magnesium aluminum spinel brick RSML-85B Silicon mullite brick RSAZM-1680 RSAZM-1650 Composite carbon and nitrogen brick RSCN-5 |

Silicon mullite brick RSAZM-1680 RSAZM-1650 | Silicon mullite brick RSAZM-1650 |

| Front kilneye | Special castable for kilneye RS-19 Tabular corundum castable RS-18K |

Special castable for kilneye RS-19 Tabular corundum castable RS-18K |

Special castable for kilneye RS-18 Steel Fibre Reinforced Refractory Castable RS-F17 RS-F16K |

Special castable for kilneye RS-18 Steel Fibre Reinforced Refractory Castable RS-F16 |

| Kiln hood | Antistrip alumina brick RSYRS-70 Mullite LCC RS-16K |

Antistrip alumina brick RSYRS-70 Mullite LCC RS-16K |

Antistrip alumina brick RSYRS-70 Mullite LCC RS-16K Steel Fibre Reinforced Refractory Castable RS-F17 |

Steel Fibre Reinforced Refractory Castable RS-F16K |

| Grate cooler | Mullite LCC RS-16K Antistrip alumina brick RSYRS-7O RSYRS-75 |

Mullite LCC RS-16K Antistrip alumina brick RSYRS-7O RSYRS-75 |

Mullite LCC RS-16K Antistrip alumina brick RSYRS-7O RSYRS-75 |

Mullite LCC RS-16K Antistrip alumina brick RSYRS-75 |

Refractory Material Selection Guide

Scientific and rational selection of refractory materials is key to improving cement kiln operation efficiency and reducing costs. We provide professional selection procedures to ensure optimal performance and cost-effectiveness.

Determine Kiln Type

Based on kiln type (wet-process or dry-process) and production characteristics, conduct preliminary screening of applicable refractory materials.

Analyze Conditions

Evaluate operational parameters including temperature, pressure, chemical corrosion intensity, and thermal shock frequency across all kiln sections.

Material Selection

Select refractory materials with proper composition and performance based on operational needs and establish optimized solutions.

Design Optimization

Optimize refractory shapes, dimensions, and installation methods by balancing construction feasibility with cost-effectiveness.

Application Cases

Our refractory products have been successfully implemented in multiple cement plants, delivering significant economic benefits to customers.

Turkish Cement Plant – 6,000t/d Production Line

Implemented third-generation refractory solutions to extend service life and reduce maintenance costs.

Cement Line Construction Project

Developed customized refractories for high-alkali conditions, featuring optimized structural design that lowered total costs.

Cement Rotary Kiln Maintenance Project

Deployed high-temperature erosion-resistant materials specifically engineered to double replacement intervals.