Fused Silica Brick

High-Grade Zero Expansion Silica Brick: Crack-Resistant at 1680℃, the Optimal Refractory for Furnace Hot Repair

Application

For lining the roofs of coke ovens, hot blast stoves, glass furnaces, tunnel kilns, melting furnaces, metallurgical electric furnaces, and carbon furnaces

Description

Fused silica brick (Fused quartz bricks) is a special refractory material renowned for its ultra-low thermal expansion rate.

Composition: High-purity silica (SiO₂ content >99%), High-temperature sintering ensures an exceptionally stable internal structure.

Key Features:

Near-zero thermal expansion – maintains dimensional stability under extreme temperature fluctuations.

Superior thermal shock resistance – minimizes cracking or spalling caused by rapid heating/cooling.

Specifications

| Item | RS-LPZ-99 | RS-LPZ-98 | |

| SiO2% ≥ | 99 | 98 | |

| Refractoriness °C ≥ | 1700 | 1690 | |

| Refractoriness Under Load °C ≥ | 1520 | 1500 | |

| Thermal Expansion | 1500°C, 2h |

+0,1 -0,4 |

|

| Apparent Porosity % | 23 | ||

| CCS MPa ≥ | 6,5 | 6,8 | |

| Bulk Density g/cm³ ≥ | 1,85 | 1,9 | |

| Color | white | white | |

| Thermal Shock Resistance 1200°C | 5 | 5 | |

| Thermal Conductivity 1200°C W/(m·K) | 1 | 1 | |

Features

Erosion Resistance

High-purity SiO₂ – exhibits outstanding erosion/acid resistance.

Low flux index (Al₂O₃ + 2R₂O): <0.3%.

Pollution-free

Fe₂O₃ content <0.1%. Zero contamination to products (e.g. glass melt)

Zero thermal expansion

No expansion joints required during repair

Enhances structural tightness of masonry

Thermal stability

No cracking during hot repairs

No spalling/flaking occurs after repair

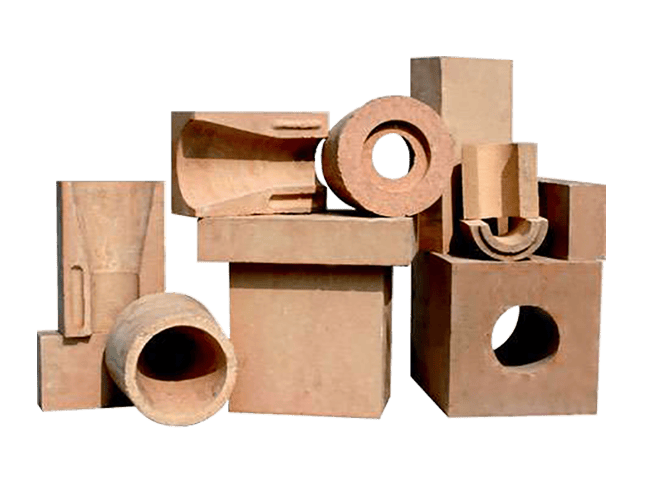

Applications

- Glass Furnace – Forehearth cover plate, Batch charging arch, Outer arch, Throat arch, Port neck arch, Inspection port

- Coke Oven – Coke oven door, Gas ascension pipe, Coking chamber, Combustion chamber

- Metallurgical Electric Furnace – Furnace Roof

- Hot Blast Stove – Stove Dome

- Tunnel Kiln – Kiln Roof

- Thermal Process Equipment – Hot maintenance

Glass Furnace

Hot repair site for the crown and batch charging port of a glass furnace

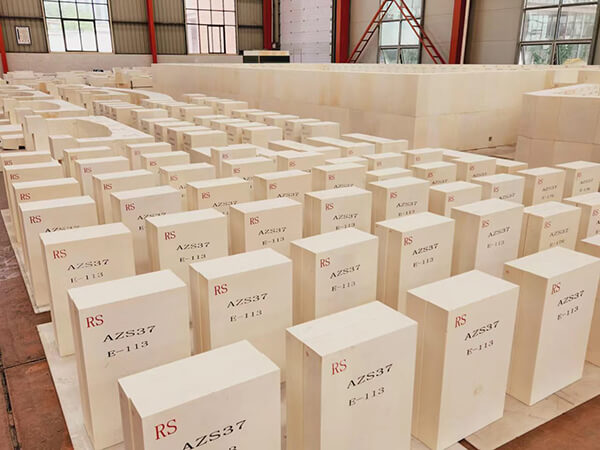

Glass Furnace

Lining the Crown of Glass Furnace. Customized shapes supported

Coke Oven

Coking chamber wall repair

Coke Oven

Construction of coke oven combustion chamber

Related Products