Silicon Nitride Bonded Silicon Carbide Bricks for Aluminum Electrolysis Cell

High resistance to cryolite erosion and enhanced oxidation resistance

Application

Ideal material for the sidewalls of large prebaked electrolyzers

Description

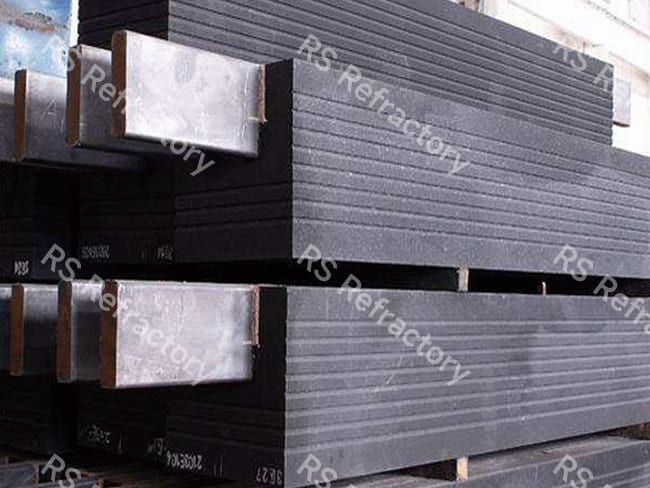

Silicon carbide (SiC) and silicon nitride-bonded silicon carbide (Si₃N₄-SiC) products are manufactured from high-quality silicon carbide and industrial silicon powder through vibration pressing followed by staged high-temperature oxidative firing. They exhibit exceptional resistance to cryolite erosion, enhanced oxidation resistance, high strength at extreme temperatures, outstanding thermal conductivity, and prolonged service life. These products serve as an ideal material for the sidewalls of large (180 kA) prebaked electrolyzers. Compared to sidewall carbon blocks, they improve current efficiency, reduce direct current consumption, and demonstrate significant energy-saving effects.

Specifications

| Item | Side Wall Brick | Corner Brick | Composite Brick |

|---|---|---|---|

| SiC % ≥ | 72 | ||

| Si3N4 % ≥ | 20 | ||

| Fe2O3 % ≤ | 0.7 | ||

| Bulk Density g/cm3 ≥ | 2.65 | ||

| Apparent Porosity % ≤ | 18 | ||

| CCS MPa ≥ | 150 | ||

| CMOR MPa ≥ | |||

| Normal Temperature | 40 | ||

| 1200°С | 45 | ||

| Service Area | Used for side wall of aluminum electrolysis cell | Used in the corner of the aluminum electrolysis cell or to fill the side distortion of the old aluminum electrolysis cell. | Used to combine silicon nitride and silicon carbide side wall bricks and carbon blocks into one body, and masonry on the side wall of the aluminum electrolytic cell. |

Carbon block for composite brick

| Item | A | B | C |

|---|---|---|---|

| Bulk Density g/cm3 ≥ | 1.57 | 1.56 | 1.50 |

| Apparent Porosity % ≤ | – | – | 22 |

| True Density g/cm3 ≥ | 1.83 | 1.89 | 1.94 |

| CCS MPa ≥ | 32 | 30 | 27 |

| CMOR MPa ≥ | – | – | 10 |

| Electrical Resistivity uQ·m | 50 | 40 | 23 |

| Thermal Expansion Coefficient (23-523 °C) X10-6°C-1 | – | – | 3.0 |

| Thermal Conductivity 1000°C W/ (m·k) | – | – | 14 |

| Ash Content % | 7 | 3.5 | 3.0 |