Refractory Materials for Aluminum Electrolysis Cells

High-performance refractory solution specifically developed for the high-temperature corrosive environment of aluminum electrolysis. It demonstrates exceptional resistance to electrolyte erosion, molten aluminum penetration, and excellent thermal shock stability, ensuring long-term safe operation and energy efficiency optimization of electrolysis cells under high-temperature and high-pressure conditions.

Service Temperature: 950-980°C Cryolite/Fluoride Salt Erosion Resistance Ultra-High Strength & Erosion Resistance Extended Cell Service Life

PRODUCT OVERVIEW

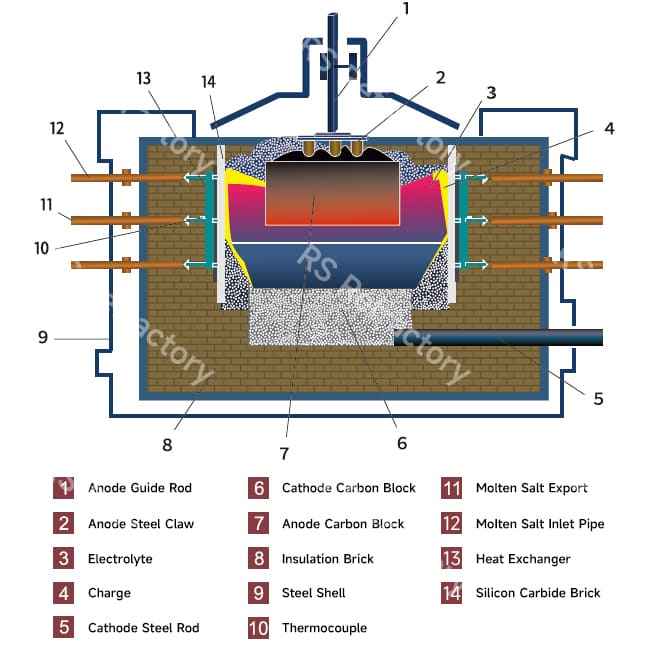

Aluminum electrolysis cells are the core equipment in aluminum production, where alumina is decomposed into metallic aluminum by passing direct current through a high-temperature molten salt electrolyte. The refractory lining of these cells must withstand prolonged exposure to temperatures around 960°C, strong chemical corrosion from molten cryolite/fluoride salts, erosion by molten aluminum, and electrochemical corrosion, while maintaining stable insulation and structural integrity.

Our refractory series, specifically developed for aluminum electrolysis cells, is manufactured using high-purity erosion-resistant raw materials (such as silicon nitride-bonded silicon carbide, penetration-resistant modified dry barrier materials, etc.) and precision processes. Validated through years of practical application in large-scale electrolysis cells, this product line offers comprehensive lining solutions for different cell types (prebaked and Søderberg) and capacity requirements. Whether for new cell construction or major maintenance repairs, we provide tailored product support.

The series exhibits excellent cryolite erosion resistance, high density, and low porosity, effectively blocking the penetration of electrolyte and molten aluminum while preventing cathode expansion and cell damage. Its outstanding thermal shock stability and balanced electrical insulation properties significantly extend cell lifespan, reduce DC power consumption and maintenance costs, and enhance production efficiency and operational safety for customers.

PRODUCT TYPES

We offer a variety of refractory materials specifically designed for aluminum electrolysis cells, meeting the requirements of different cell components and process conditions.

Side wall, corner of the electrolysis cell; combine with carbon blocks

Filling the corners of electrolytic cells, laying silicon carbide bricks

Anti-infiltration layer, Steel rod zone, Base insulation layer, Lightweight brick masonry

Used as a buffer layer; for filling joints between carbonaceous blocks

APPLICATION EXAMPLES

Our refractory materials are widely used in various aluminum smelting enterprises, providing reliable protection for production facilities of any scale and technological processes.

600kA Prebaked Cells

Our self-developed high-thermal-conductivity reaction-sintered silicon carbide bricks are adopted, effectively blocking electrolyte penetration and reducing replacement frequency and maintenance costs caused by corrosion.

Dry Barrier Material

Effectively prevents molten aluminum from damaging the bottom insulation materials, optimizes the refractory lining structure at the electrolysis cell bottom, and reduces the consumption of other refractories as well as construction investment.

Cell Bottom Lining

Through the selection of high-purity raw materials and the application of microporous technology, the penetration and erosion resistance of high-performance clay bricks have been significantly enhanced, while remaining economically practical.

PRODUCT ADVANTAGES

Our specialized refractory materials for aluminum electrolysis cells offer significant advantages over comparable products

Extended Service Life

Utilizing top-grade raw materials such as silicon nitride-bonded silicon carbide and ultra-fine powder reinforced corundum, combined with high-pressure forming and sintering processes, the resistance to electrolyte penetration is markedly improved.

Exceptional Erosion Resistance

Designed specifically to withstand corrosion from cryolite/fluoride salt melts, these materials form a dense reactive barrier that effectively suppresses cathode spalling and sidewall damage while reducing the frequency of anode effects.

Superior Thermal Shock Stability

A unique matrix formulation endows the material with an ultra-low thermal expansion coefficient, enabling it to withstand frequent current fluctuations during electrolysis, thereby eliminating the risk of lining cracking.

Reduced Comprehensive Costs

The material combines balanced electrical conductivity with thermal insulation properties, helping to maintain stable cell voltage. DC power consumption per ton of aluminum is reduced by 2-3%, achieving substantial electricity cost savings.

TECHNICAL SUPPORT AND SERVICE

We provide a full range of technical support and services to ensure optimal product performance

Customized Solution Design

We develop tailored refractory selections and optimized lining schemes based on customer furnace type, specifications, technological features, and operating conditions.

On-Site Technical Guidance

We dispatch professional technical personnel to ensure strict installation control, guarantee construction quality, and optimize refractory performance.

After-Sales Service

We conduct regular furnace inspections and audits, providing maintenance recommendations and repair solutions to extend equipment service life.