Aluminum Silicate Fiber Board

Low heat capacity, low thermal conductivity, long service life

Application

Widely used for thermal insulation of heating aggregates

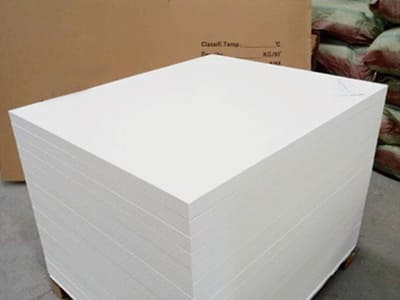

Description

Aluminosilicate boards are produced by melting selected fireclay in electric furnaces at temperatures exceeding 2000°C, followed by mechanical fiber spraying, uniform addition of binders, oil-repellent and hydrophobic agents, and thermal curing.Specifications

| Item | PXB-1000 |

|---|---|

| Long Term Service Temperature °С | 1000 |

| Al2O3 % ≥ | 45 |

| Al2O3+SiO2 % ≥ | 96 |

| Fe2O3 % ≤ | 1.5 |

| R2O % ≤ | 0.5 |

| Thermal Conductivity W/(m· K) ≤ | 0.14 |

| Density kg/m² | 280-800 |

| Linear Shrinkage 1150°C×6h % ≤ | 4 |

| CCS MPa | 0.4-1.5 |

Features

- High compressive strength and long service life

- Low heat capacity and low thermal conductivity

- Non-brittle material with high toughness

- Precise dimensions and excellent flatness

- Easy cutting and installation, convenient construction

- Excellent wind erosion resistance

- Continuous production with uniform fiber distribution and stable performance

- Good sound absorption and noise reduction properties

Applications

- Ferrous Metallurgy: Expansion joints, lining insulation, insulating gaskets, and foundry mold insulation.

- Non-Ferrous Metallurgy: Backup insulation materials for linings, covers for tundishes and launder systems for copper and copper alloy casting.

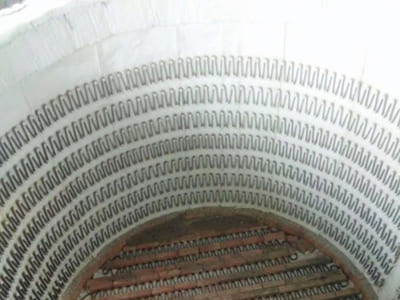

- Ceramic Industry: Lightweight kiln car structures and hot face insulation linings for kilns, kiln temperature zone segregation, and flame baffle materials.

- Glass Industry: Molten glass bath backup insulation, burner blocks.

- Furnace Engineering: Refractory materials for hot face applications (replacing fiber blankets), backup insulation for dense refractories, expansion joints.

- Building Materials Industry: Equipment insulation such as for rotary cement kilns.