α β-Al2O3 corundum brick

Material: High-purity Al₂O₃ Melting Point: >2000°C Phases: α/β-corundum Properties: High purity, glass phase-free, no glass contamination

Application

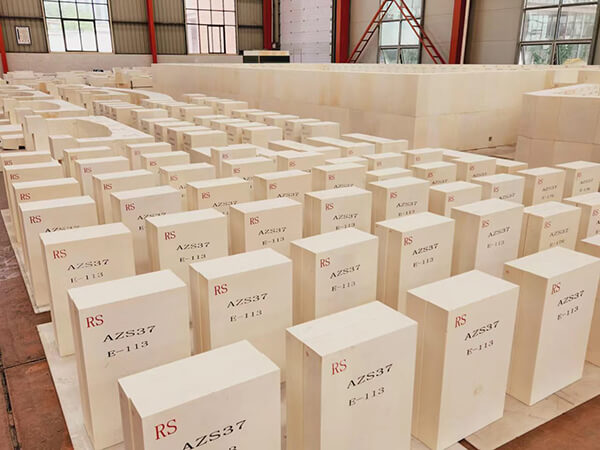

Optimal Refractory Materials for Key Zones of Glass Furnaces

Description

Fused α-β Corundum Brick (Electrically Fused Cast Corundum/Alumina Bricks) consists of approximately 50% α-corundum and 50% β-corundum. The interweaving of these two crystalline phases forms an extremely dense structure with excellent resistance to strong alkalis.

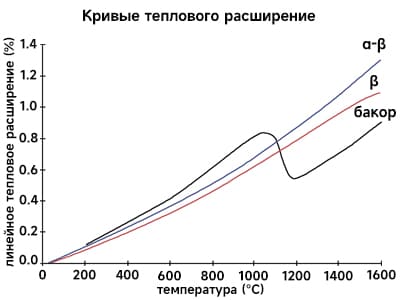

In the temperature range up to 1350°C, its resistance to molten glass is comparable to AZS refractories (Bakor). Due to the almost complete absence of Fe₂O₃ and TiO₂ impurities, as well as minimal glass phase content, this material exhibits superior characteristics: when in contact with molten glass, it hardly forms bubbles or foreign inclusions, eliminating contamination of the glass melt.

Therefore, it is ideally suited for lining the working basins of high-quality glass furnaces, glass receiving channels, and distribution ducts. It offers an optimal balance of performance and cost-effectiveness.

Specifications

| Item | α-β Al2O3 | α Al2O3 | β Al2O3 |

| Chemical Composition, Mass % | |||

| Al2O3 ≥ | 94 | 98,5 | 93 |

| SiO2 ≤ | 1 | 0,4 | – |

| NaO2 ≤ | 4 | 0,9 | 6,5 |

| Other Impurities ≤ | 1 | 0,2 | 0,5 |

| Crystalline Phase Analysis | |||

| α Al2O3 | 44 | 90 | – |

| β Al2O3 | 55 | 4 | 99 |

| Permanent Linear Change, 1500°C×2h, %, ≤ | 1 | 6 | 1 |

Applications

Fused α-β corundum brick expands application areas with its exceptional cost-performance ratio:

- Lining of working basins and forehearths in high-end glass furnaces

- Glass receiving channels and distribution ducts

- Comparable erosion resistance to glass melt as AZS (Bakor) at temperatures up to 1350°C

- Minimal glass phase content (<1%):

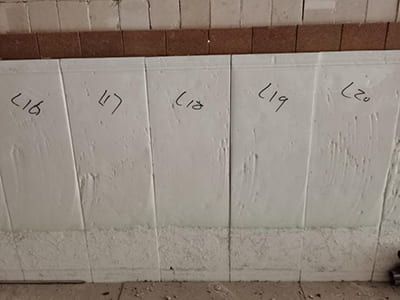

As shown in the above figure, the degree of erosion of the α-β corundum lining in the working basin of a float glass furnace is demonstrated. After a full campaign cycle of operation: The main mass of the α-β corundum lining shows no signs of erosion; Slight wear marks are only observed at the contact line with the glass melt level.

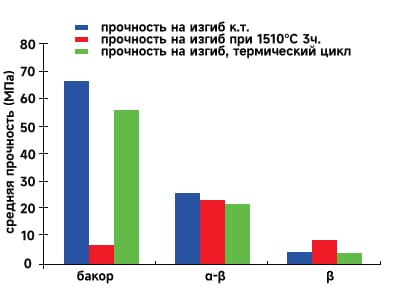

New Application Area (1) – Refractory Lining for the Vault of Oxygen-Fired Glass Furnaces

- AZS Brick (Bakor):

- Flexural Strength Limit at 20°C: ~70 MPa

- At 1510°C: <10 MPa (Significant Deformation + Glass Phase Precipitation)

- α-β Corundum Brick:

- Maintains Strength >20 MPa at 1510°C

- No Deformation or Glass Phase Migration

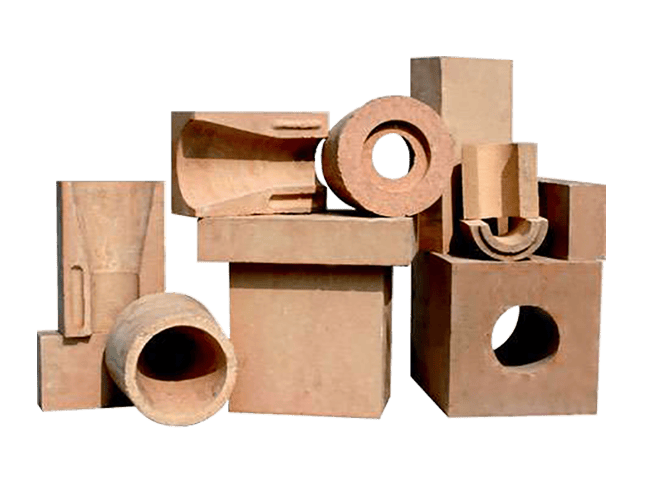

New Application Area (2) – Electrolyzers for Special Metallurgy

As shown in the figure, the α-β corundum brick for metallurgical applications is almost free from erosion after a full production cycle.

Related Products